Indonesian Coconut — Whole Coconut Intake SOP, Grading, and Region Tags | IndoNatureGoods.com

Follow this Indonesian coconut intake SOP to grade whole coconuts consistently. See simple acceptance bands, size/weight tables, defect codes, and region tags. IndoNatureGoods.com explains field cues and intake steps for mature coconut and young coconut. Product-only scope keeps approvals fast and volumes predictable.

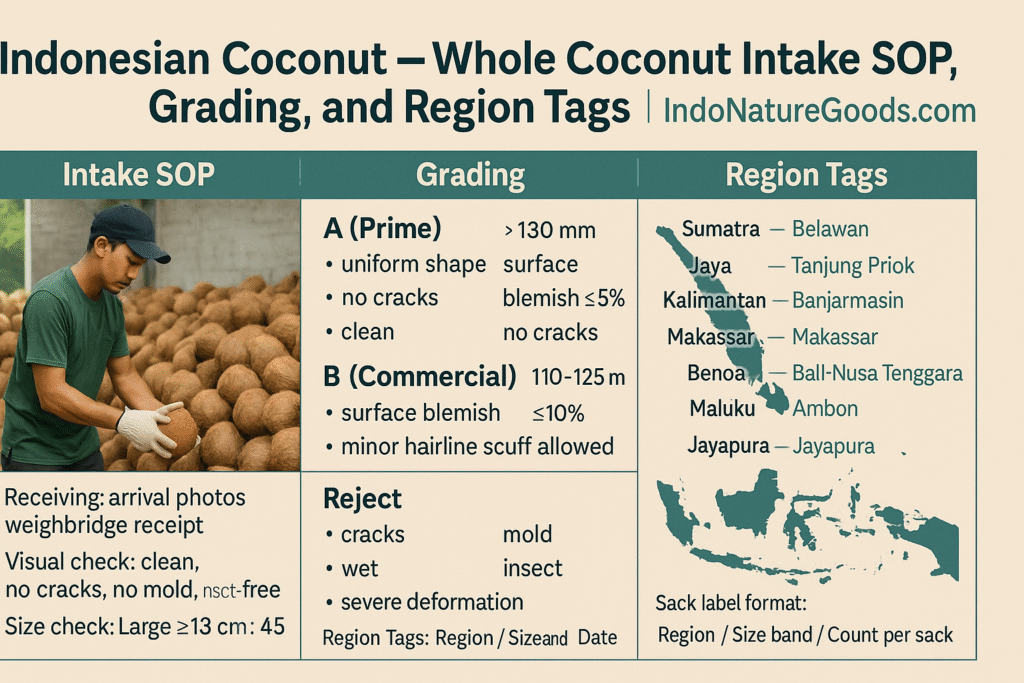

Headline — coconut intake SOP for fast, consistent grading

Whole coconut moves quickly when intake rules are clear and repeatable.

Introduction (hook, global context) — coconut intake that speeds approvals

Teams need one checklist. Therefore, this coconut intake SOP defines grade language, size bands, and defect codes. Consequently, intake time drops and counts stay honest.

The Global Demand (why this product is important) — coconut quality at the door

Retail and foodservice depend on whole coconut freshness and appearance. Hence, intake is the gatekeeper. Simple rules protect margins and reduce waste.

Why Choose Indonesian coconut (Indonesia’s superiority) — uniform outcomes

Indonesia supplies whole coconut year-round from multiple belts. As a result, one intake SOP works across Sumatra, Java, Sulawesi, and Maluku.

About IndoNatureGoods.com (supplier profile) — coconut discipline at source

IndoNatureGoods aligns farm teams and graders on the same coconut language. Moreover, region tags and band tables travel with each lot.

Product Range (whole only) — coconut scope and band logic

-

Mature coconut (brown coconut): whole; semi-husked or dehusked per SOP; bands S/M/L/XL.

-

Young coconut (green coconut): whole; trimmed to market style; fixed counts per bundle or carton.

This lane remains whole coconut only. No derivative products.

Coconut intake station — setup and tools

-

Coconut scale: calibrated for band checks.

-

Coconut ring/circumference gauge: quick size confirmation.

-

Coconut ticket & marker: lot ID, region, date, band, and remarks.

-

Coconut defect board: short, visible codes for fast decisions.

Quality Assurance — coconut intake in four quick steps

-

Coconut shell & crown check: firm shell, sound crown, no cracks.

-

Coconut cleanliness check: low surface soil; tidy trim on young fruit.

-

Coconut size/weight check: match S/M/L/XL band table with ± tolerance.

-

Coconut freshness cues: young = bright husk; mature = dry husk with steady shake feel.

Record the result. Consequently, grading reads the same across crews.

Coconut size bands — one table that travels

Define coconut bands by weight or circumference. Freeze the values at RFQ. Then print them on tickets and station boards. Therefore, disputes fall and throughput rises.

Coconut defect codes — short words that speed decisions

Use the same four codes across regions:

-

CS (coconut cracked shell) → reject.

-

OT (coconut over-trim) → reject.

-

HS (coconut heavy soil) → rework clean or reject by rule.

-

OB (coconut off-band) → reclassify or reject.

Furthermore, add a remark line when variance appears repeatedly.

Coconut recheck lane — small loop, big impact

Flag coconut lots with >X% defects. Shift them to a recheck lane. Consequently, clean lots keep moving while issues resolve without blocking intake.

Coconut region tags — origin clarity on every ticket

Attach a region code to each coconut lot: SU (Sumatra), JV (Java), SL (Sulawesi), MK (Maluku). Additionally, note the harvest week. Therefore, planners match volumes to real calendars.

Coconut rotation hints — using tags in planning

-

SU coconut: strong baseline counts most months.

-

JV coconut: tight calendars and quick transfers.

-

SL coconut: flexible surge coverage.

-

MK coconut: stable shells and low rejects in routine weeks.

Rotation with tags keeps programs steady through weather shifts.

Why Choose IndoNatureGoods.com (reasons for choosing) — coconut intake strengths

-

One coconut intake SOP across regions.

-

Visible band tables and defect codes.

-

Region tags that align calendars to real harvest windows.

The Human Side — coconut livelihoods with clear SOPs

Consistent coconut rules help harvesters and graders work faster and safer. Training deepens. Families gain steadier income as programs hold their schedule.

How to Partner — coconut intake onboarding in five steps

-

Share whole coconut type, weekly counts, and preferred regions.

-

Approve the band table and tolerance.

-

Approve the defect codes and ticket layout.

-

Run a pilot week with station photos.

-

Lock the SOP and scale to monthly cycles.

Testimonials — coconut buyer remarks

“Coconut intake took minutes; band and defect codes were obvious.”

“Region tags helped planning and reduced surprises.”

Future — coconut intake visibility

Expect photo checklists and digital tickets for whole coconut. Consequently, audits shorten and crew onboarding gets easier.

Final Thoughts — coconut intake that keeps programs steady

Fix the band table. Use short defect codes. Tag the region. With that discipline, whole Indonesian coconut reads clean at intake and ships on a reliable clock.

FAQs (5) — coconut intake SOP

-

Which whole coconut types does the SOP cover? Mature brown coconut and young green coconut.

-

How are coconut bands defined? By weight or circumference with a stated ± tolerance.

-

What happens to off-band coconut? Reclassify or reject per OB code.

-

How do region tags help coconut planning? Tags align volumes to harvest windows and rotation.

-

Can we customize coconut defect codes? Yes—keep words short and publish the list on tickets.