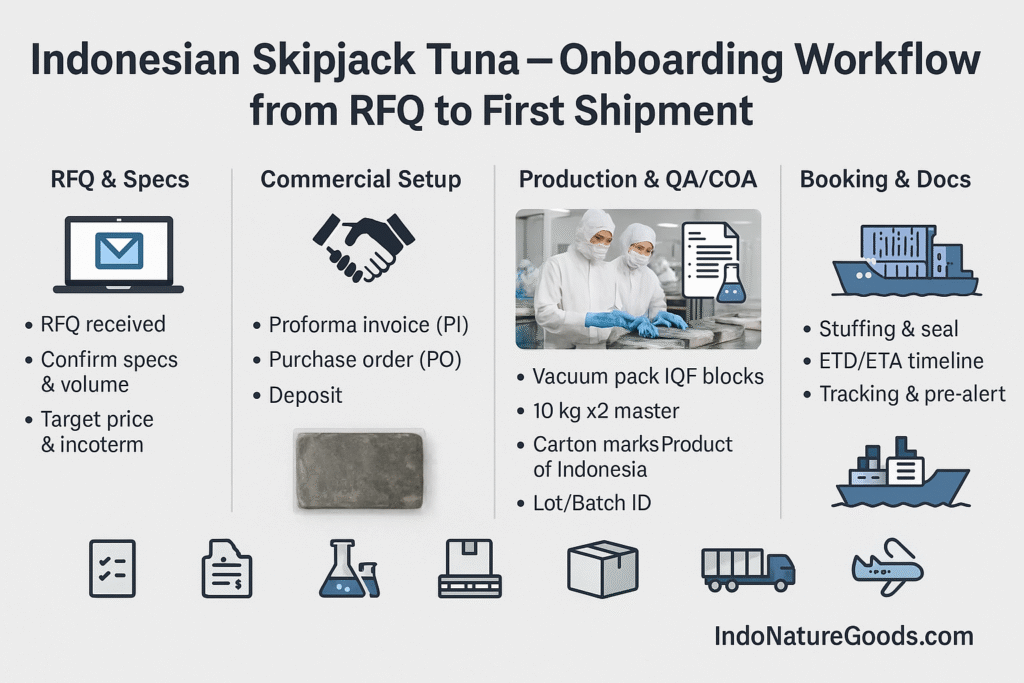

Indonesian Skipjack Tuna — Onboarding Workflow from RFQ to First Shipment | IndoNatureGoods.com

A clear Indonesian Skipjack Tuna onboarding guide from RFQ to first shipment. Align specs, COA fields, label proofs, pallet plans, and document timing. IndoNatureGoods.com shows milestone evidence, QA gates, logistics rhythm, and a buyer-friendly checklist that speeds approvals and protects ETAs.

Headline — Skipjack Tuna onboarding for wholesale and export buyers

This Skipjack Tuna onboarding workflow removes friction and speeds the first PO.

Introduction (hook, global context) — Skipjack Tuna onboarding that moves fast

Global teams value clarity and predictable files. Therefore, our Skipjack Tuna onboarding aligns specs, QA, and documents before production starts.

The Global Demand (why this product is important) — Skipjack Tuna scale needs process

High-volume programs need reliable Skipjack Tuna inputs for canning, loins, steaks, and flakes. Consequently, a disciplined onboarding plan protects budget and timelines.

Why Choose Indonesian Skipjack Tuna (Indonesia’s superiority) — quick setup

Indonesia offers rich Skipjack Tuna grounds, skilled plants, and short lanes to ports. As a result, onboarding steps connect quickly to loading calendars.

About IndoNatureGoods.com (supplier profile) — Skipjack Tuna onboarding owner

IndoNatureGoods publishes versioned Skipjack Tuna specs, COA templates, label proofs, and milestone schedules. Moreover, we attach time-stamped photos that match each step.

Product Range (detailed specifications) — Skipjack Tuna formats we onboard

Skipjack Tuna Whole Round, G&G, Loins, Steaks, and Flakes/Chunks. Each format carries acceptance bands, trim notes, and packaging logic for fast sign-off.

Quality Assurance (quality guarantee, certification) — Skipjack Tuna QA in onboarding

HACCP plants with GMP/SSOP. COA per Skipjack Tuna lot for microbiology and policy tests. Additionally, method notes and acceptance ranges appear on forms to speed audits.

The Export Process (packaging, logistics, payment) — Skipjack Tuna onboarding rhythm

We map pallet plans, reefer settings, carton labels, and route timing during onboarding. Draft documents arrive early, and final sets match L/C or T/T milestones. Consequently, ETAs hold and claims remain rare.

Why Choose IndoNatureGoods.com (reasons for choosing) — Skipjack Tuna onboarding advantages

-

Evidence-first files for Skipjack Tuna approvals.

-

Clear calendars and freeze dates for slots and sailings.

-

Responsive change logs when drivers move.

Skipjack Tuna Onboarding — RFQ and scope alignment

Share your Skipjack Tuna format, yield goals, and target Incoterms. We return a structured RFQ form with acceptance bands, carton marks, and pallet specs. Therefore, teams compare apples to apples from the first email.

Skipjack Tuna Onboarding — specification lock and templates

We deliver versioned Skipjack Tuna specs and COA fields. You mark edits. Then we freeze the template and publish a slot calendar with pack dates and ETD/ETA.

Skipjack Tuna Onboarding — label proofs and regulatory checks

Artwork and claims follow destination rules. We align ingredient statements, allergen lines, and net content language. Consequently, labels pass internal review without late surprises.

Skipjack Tuna Onboarding — QA sampling and COA flow

We agree sampling sizes and methods. During packing, COAs for Skipjack Tuna lots carry micro results, policy tests, and method notes. Files arrive in the format your compliance team prefers.

Skipjack Tuna Onboarding — pallet plans and cold chain setup

We define carton orientation, pallet height limits, wrap tension, and corner boards. Furthermore, we confirm reefer set-points and VGM timing. This plan reduces damage and keeps airflow balanced.

Skipjack Tuna Onboarding — milestone evidence and document timing

You receive packing photos, seal photos, gate-in, and on-board confirmations. Draft invoice and packing list arrive early. Final Skipjack Tuna sets include COO, health certificate, COA, and B/L.

Beyond Skipjack Tuna (other products for procurement)

Coffee beans, ginger, bird nest, coconut, squid, charcoal briquette, hardwood charcoal.

The Human Side (impact on local communities) — Skipjack Tuna jobs and training

Structured Skipjack Tuna onboarding stabilizes shifts, expands training, and improves safety. Families benefit from steady work and clear calendars.

How to Partner (how to collaborate) — Skipjack Tuna onboarding checklist

-

Send Skipjack Tuna formats, bands, and Incoterms.

-

Approve specs, COA fields, and label proofs.

-

Confirm pallet plan and route card.

-

Align draft and final document windows.

-

Lock slot and pack dates; receive milestone evidence until on-board.

Testimonials (buyer trust) — Skipjack Tuna onboarding references

“Skipjack Tuna templates cut our review time. First shipment cleared exactly as planned.”

“Photo logs and COAs matched the spec and kept finance comfortable.”

Future (industry trends & sustainability commitments) — Skipjack Tuna onboarding outlook

Expect more digital trace packs, live temperature feeds, and standardized COA data. We support practical tools that shorten audits and clarify claims.

Final Thoughts (elegant closing) — Skipjack Tuna onboarding that protects timelines

Freeze the spec. Approve the labels. Set the calendar. With that plan, Indonesian Skipjack Tuna onboarding moves quickly and stays auditable.

FAQs (5) — Skipjack Tuna onboarding

-

What do you need for an RFQ? Format, grades, volume, Incoterms, and destination rules.

-

How fast can we lock a spec? After one edit cycle on the Skipjack Tuna template.

-

Which COA fields are standard? Micro plus policy tests with method notes and acceptance bands.

-

How do we prevent document delays? Drafts early, final sets tied to milestones.

-

Do you support a pilot shipment? Yes—pilot Skipjack Tuna lots validate templates, QA, and timing before scale.