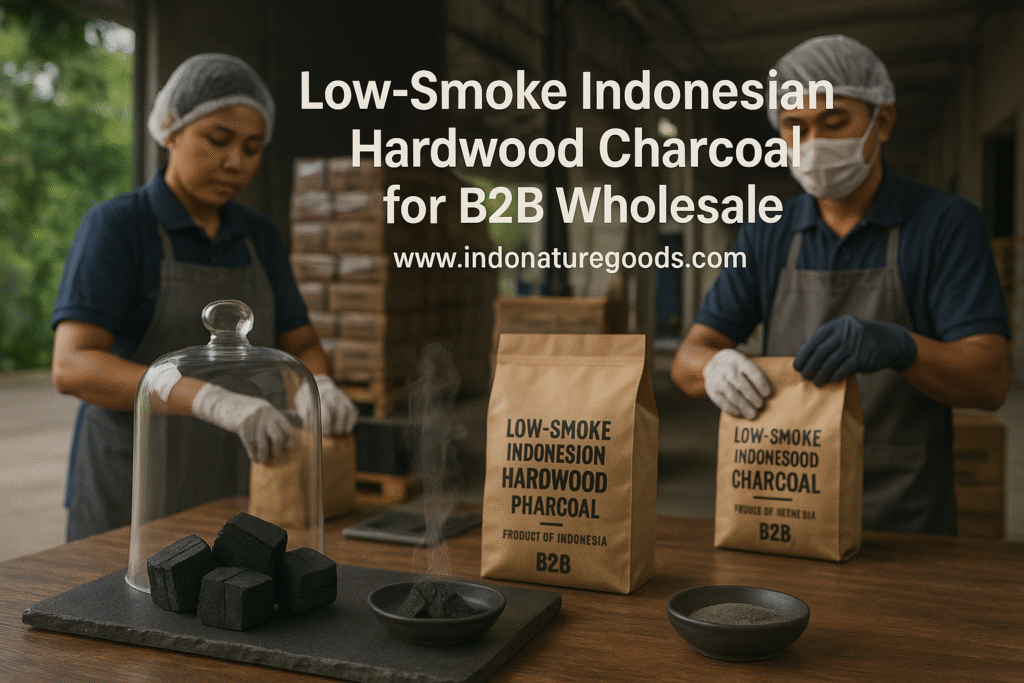

Low-Smoke Hardwood Charcoal for B2B Wholesale

Smoke control matters in open kitchens and lounges. Low emissions protect flavor and speed service. Indonesian Hardwood Charcoal helps you hit those goals. It lights well. It burns clean. It ships with complete documents. Consequently, your team spends less time firefighting and more time serving customers.

Demand shifts by season. Routes change with port traffic. However, a clear spec and routine QA keep performance steady. Therefore, distributors protect SLAs and reduce claims.

Hardwood Charcoal Global Demand

Live-fire menus are growing worldwide. As a result, buyers request Hardwood Charcoal with less smoke and fewer pops. Year-round demand also pushes consistency across lots. Moreover, retailers now require cartons that survive stacked storage and long routes.

Compliance adds pressure. Labels must scan. Warnings must follow local rules. Hence, suppliers who control quality and documentation win shelf space and repeat orders.

Why Choose Indonesian Hardwood Charcoal

Indonesia offers plantation hardwood sources and kiln expertise. Proper curing lowers volatiles; screening reduces fines. Consequently, heat stays strong while smoke stays low. Port access supports reliable ETDs for FCL or LCL, which helps planning.

Standardized specs make growth realistic. Lock the size band, moisture target, and fines limit per market. Forecasts become clearer. Downstream handling gets easier. Reorders move faster.

About indonaturegoods.com (Hardwood Charcoal Supplier)

indonaturegoods.com links importers and distributors to audited mills and dependable forwarders. Origin is verified, kiln routines reviewed, and moisture targets set. Additionally, bag stitching, carton compression, and pallet integrity are tested. Bookings are secured early; loading photos and seal numbers are shared.

Our role is risk control. We align specs with your channel. Then we publish a critical path and track milestones. Finally, we deliver complete paperwork so customs clears quickly.

Hardwood Charcoal Quality Assurance

Quality starts with numbers you can check. We lock ash, moisture, size distribution, and fines percent. Furthermore, we run sample burns and note ignition behavior, heat curves, and residual ash.

Packaging receives equal rigor. Compression and drop tests protect cartons. Corner boards and tight wrap keep stacks square. Pre-shipment inspections add another layer. Moreover, third-party inspection (SGS/BV) is available on request.

Hardwood Charcoal Export Process

A clear process protects SLAs and margin:

-

Specs & Terms — size band, fines tolerance, moisture targets, FOB/CFR/CIF.

-

Labels & Compliance — HS marks, barcodes, warnings, languages.

-

Production & Packing — drying routines, bag type, master cartons, pallet plan.

-

Bookings & ETD/ETA — aligned to forecasts, promotions, and seasonality.

-

Documents — Commercial Invoice, Packing List, COO, optional inspection, plus loading photos and seal numbers.

Dry cargo travels safely. Therefore, moisture is controlled, containers are vented when needed, and evidence is archived for each shipment.

Why Choose indonaturegoods.com for Hardwood Charcoal

One accountable partner from mill to vessel. Communication is proactive; risks are flagged early. Buffers cover holidays and weather. Consequently, downstream customers stay supplied during peaks.

ETDs are set realistically. Alternates and backup capacity are maintained. As a result, your program remains stable while you scale SKUs and regions.

Beyond Hardwood Charcoal

We can consolidate more Indonesian categories under one compliant workflow: skipjack tuna, coffee beans, ginger, bird nest, coconut, and squid. Vendor count drops. Compliance stays centralized.

The Human Side of Hardwood Charcoal

Stable purchase orders support mill workers and packers. Safer kilns protect nearby communities. Stronger cartons reduce injuries and rework. Therefore, quality gains deliver real local value.

How to Partner on Hardwood Charcoal

Start with a brief checklist:

-

Share size band, fines tolerance, volumes, and destination ports.

-

Confirm label languages, barcode rules, and audit needs.

-

Receive tiered pricing, a production calendar, and a compliance checklist.

-

Begin production after deposit or L/C at sight.

-

Get loading photos, seal numbers, and ERP-ready tracking updates.

Hardwood Charcoal Testimonials

“Smoke dropped. Service ran smoother.” — UK distributor

“Heat stayed stable. Guests noticed the flavor.” — EU importer

“Cartons held shape. Claims fell.” — US wholesaler

Future of Hardwood Charcoal

Traceability will deepen. Retort technology will cut smoke and improve yield. Additionally, digital paperwork will speed audits. Suppliers with proof and data will win chain approvals and longer contracts.

Final Thoughts on Hardwood Charcoal

Choose fuel that keeps smoke low and service high. Write a clear spec. Test against that spec. Then ship with disciplined packing and complete documents. Indonesian Hardwood Charcoal makes that plan practical.

Hardwood Charcoal FAQs

Q1: What drives smoke in hardwood charcoal?

A: Moisture and volatiles. Proper curing and storage reduce both.

Q2: How do you set moisture targets?

A: Targets are set per market and verified before loading.

Q3: Can you prove low smoke before shipment?

A: Yes. Sample burns and moisture checks are logged per lot.

Q4: What packaging helps keep pallets square?

A: Strong cartons, corner boards, and tight wrap matched to the route.

Q5: What lead time should I plan for?

A: Typically 2–4 weeks after deposit or L/C at sight. Add buffers during peaks.